“Alnovi” Superplastic Aluminum Alloy Can be Molded Freely Like Plastic

EVs, ships, aircraft equipment, rolling stock, architecture

“Alnovi” superplastic molds

can be used to create complex designs,

greatly expanding the expressive ability of aluminum plate.

Superplastic molding is a forming method that utilizes the remarkable ductility exhibited by aluminum at high temperatures, making it possible to mold difficult-to-machine components integrally as single pieces.

UACJ Corporation’s “Alnovi” has excellent superplastic properties and is extensively used for low-temperature or high-speed molding of difficult-to-machine components for applications such as automobiles and aircraft.

Furukawa Sangyo supplies Alnovi to a wide range of molding companies (Tier-1) in Japan and overseas involved with EVs, aircraft, and rolling stock, and also contributes to reducing the weight of structures and lessening the labor and time of joining work required for them through integral molding.

About Alnovi

Alnovi is a superplastic aluminum alloy that can be freely molded like plastic.

UACJ's Alnovi superplastic molding aluminum plates were created to further expand the application of superplastic alloys, which were developed primarily for use in aerospace equipment.

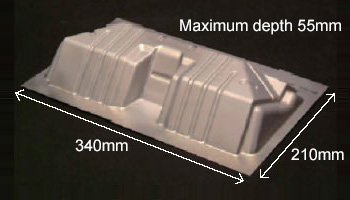

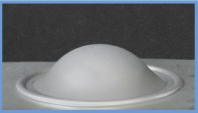

By utilizing its high elongation properties, Alnovi can be used to mold deep and complex uneven shapes.

Compared to conventional superplastic alloys, it allows molding at higher speeds and has superior corrosion resistance and weldability.

It is ideal for lightweight structural materials such as automobile body panels with a high sense of design, rolling stock outer panels, building materials, and housing exterior products.

Features

- It allows molding at higher speeds than conventional superplastic alloys.

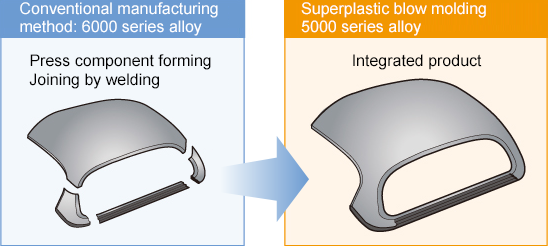

- It can be used for integral molding of products and can thereby reduce the number of components and welding points.

- Molding can be performed with only one side of the mold, reducing costs.

- Complex shapes and highly flexible designs can be molded.

- It has excellent transferring properties.

- It has excellent shape-fixing properties (no springback).

Superplastic Molding

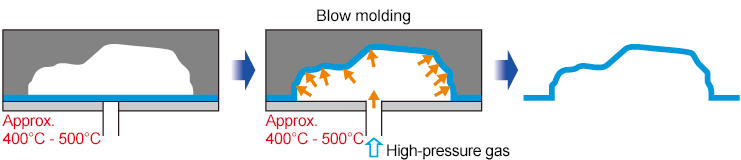

Superplastic alloys can exhibit high elongation of 200% - 1,000% at high temperatures of approximately 400°C - 500 °C.

By utilizing these properties, complex shapes like those formed from plastic can be created through blow molding despite being metal alloys.

| Item | Press molding | Blow molding |

|---|---|---|

| Molding temperature | Room temperature | Approx. 500°C (mold + material heating) |

| Molding time (strain-rate (/s)) |

Several seconds (1 to 10) |

Several minutes - several tens of minutes (0.01 to 0.001) |

| Changes in plate thickness | Small degree of change | Large reduction in plate thickness |

| Productivity | Suitable for mass production | Suitable for small lots Low springback |

| Molding time |  |

|

Applications

Automobiles (body panels, optional parts, components, interior and exterior panels), construction materials (residence doors, gate doors, fences, building material exterior walls, interior walls, ceilings, access floors)

Medicine (electronic equipment cases, electromagnetic shielding), precision models, decorative items

Components and Properties

| Plate thickness | 0.3~3.0 mmt |

|---|---|

| Plate width | 1,600 mm (maximum) |

| Plate length | 4,000 mm (maximum cut) |

| Thermal refining | H18 |

| Si | Fe | Cu | Mn | Mg | Zn | Cr | Al |

Notes |

|

|---|---|---|---|---|---|---|---|---|---|

| Alnovi-1 | < 0.1 | < 0.1 | < 0.1 | 0.4 to 1.0 | 4.0 to 4.9 | < 0.1 | 0.05 to 0.25 | Remainder | 5083 SPF |

| Alnovi-U | < 0.1 | < 0.1 | < 0.1 | 1.0 to 1.7 | 4.0 to 4.9 | < 0.1 | < 0.1 | Remainder | Series 5000 SPF |

| Tensile strength (N/mm2) | Yield strength (N/mm2) | Elongation (%) | Fatigue strength 107 (N/mm2) | |

|---|---|---|---|---|

| Alnovi-1 | 275 to 350 | 125 to 200 | ≧ 16 | 150 |

| Alnovi-U | 295 to 370 | 135 to 210 | ≧ 16 | 160 |

| Superplastic elongation (%) | m-value (strain-rate sensitivity index) | |

|---|---|---|

| Alnovi-1 | 300 to 500 | 0.5 |

| Alnovi-U | 300 to 500 | 0.5 |

Click here for inquiries regarding this article

Related articles

-

“Alnovi” Superplastic Aluminum Alloy Can be Molded Freely Like Plastic

EVs, ships, aircraft equipment, rolling stock, architecture

-

Supporting the efficiency of inspection work with AR!

Accessories inspection support systemInfrastructure and Plant

-

New value creation through inspection / investigation work using drones and through the developed body

Infrastructure and Plant

-

-

Ventilation system utilizing geothermal heat

Construction, Eco-friendly and Disaster Prevention